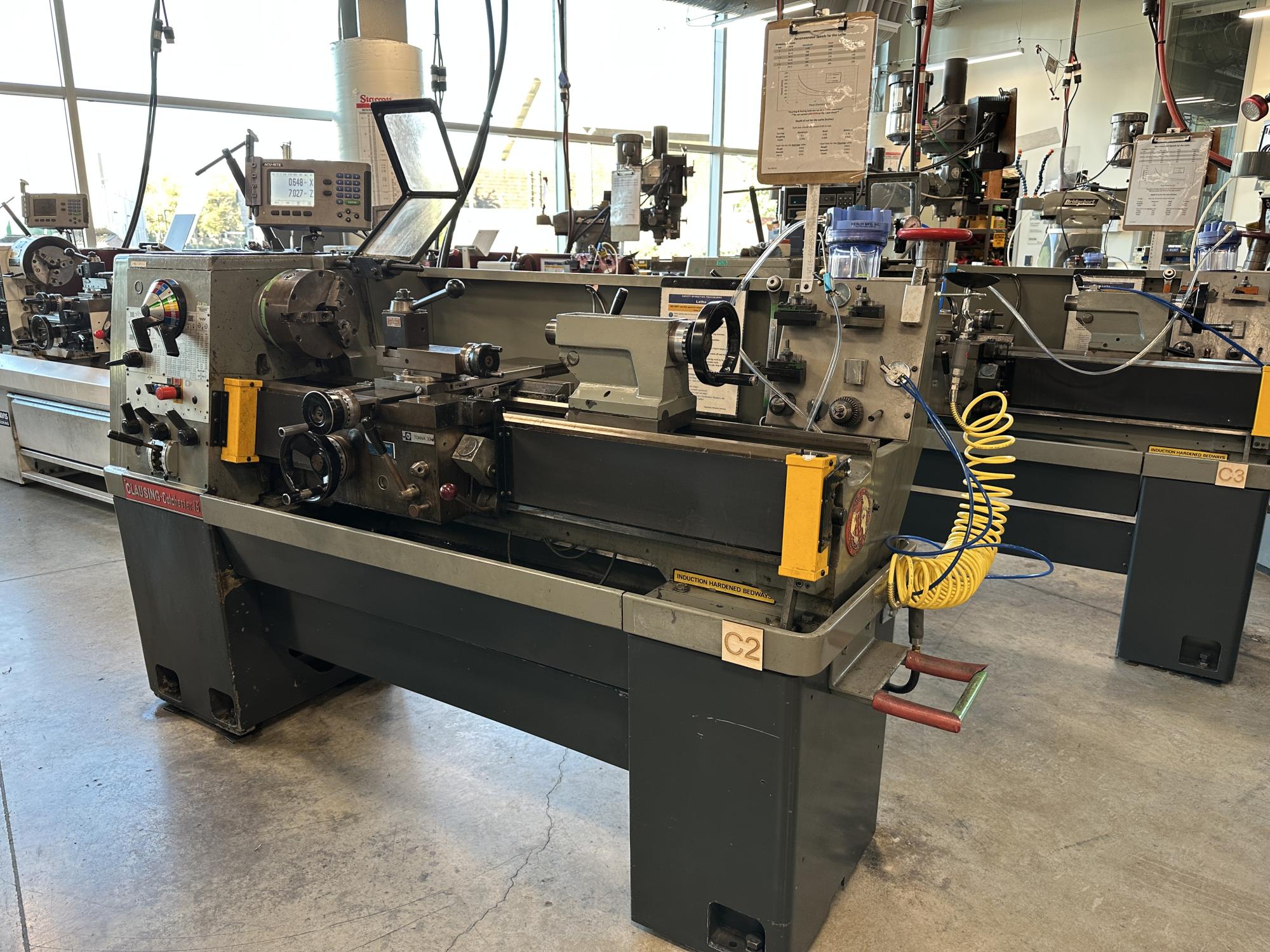

Turning at the ESDC

Turning is essentially just a machining process performed on a lathe used primarily for cylindrical parts like shafts, bearings, threaded fasteners, etc. The technique is valued for precisions, versatility and efficiency. Here at the ESDC, we have 10 manual Clausing-Colchester and Harrison lathes equipped with digital readouts for precise measurements. Like milling, turning can be done on just about any types of materials like metals, plastics, and wood. With turning, user can produce a wide range of shapes, from straight and tapered profiles to contoured and grooved designs. Users are also free to adjust cutting parameters like feed rates and spindle speeds to achieve different surface finishes. This way, users sometimes don't need to perform other finishing processes. Moreover, turning is also cost-effective, as it minimizes material waste and provides precise control over the machining process. This makes it suitable for producing high-quality components in both small-scale and industrial manufacturing settings.

Materials we offer to turn:

- Metals

- ESDC offers a variety of metals to be used for turning like Steel, Aluminum, Brass and Copper. Some materials are harder like steel requires more techniques with spindle speed, cutting depth and cooling for a good surface finish.

- Plastics

- A lot of thermoplastics could also be used for turning, like Nylon, Polypropylene, polycarbonate and acrylic could be used for turning.

- Composites

- Some composite materials like Carbon Fiber and Glass-Reinforced Plastics can be used for turning. Although they are more tricky to do that requries special tooling.

- Wood

- A lot of wood can also be used for turning like Pine, Cedar and Redwood.

Lathe tolerances

| Finishing tolerance | +/- 0.005" |

| Default surface finish | Ra 125µ" |

| Spindle Speed | Up to 2500 RPM |

| Minimum piece size (Diameter) | 1/4" |

| Swing Over Bed (Diameter) | 13" |

| Swing Over Cross Slide | 8.26" |